All candles have a warning label attached to them, warning us of the dangers of lighting it and precautionary tales of what to do and what not to do. I noticed that one of those suggestions is to burn the candle on a “heat-resistant surface.” This got me thinking, “What is a heat-resistant surface that would be considered safe to burn a candle on?” I went to the internet to find out and this is what I discovered!

What are heat-resistant, safe surfaces to burn candles on? Heat-resistant surfaces are those that do not burn easily or heat up quickly and are made to withstand warm temperatures. Good examples of heat-resistant surfaces that would be good to burn candles on include stovetops; kitchen countertops, such as granite; and other tables, chairs, or shelves with fire-resistant, treated wooden surfaces.

How do you know if a bookshelf, table, or other surface is made of treated, fire-resistant wood? I did some research to find out about how these products are made, how they are categorized, and how they are classified “heat-safe” or “fire-resistant.”

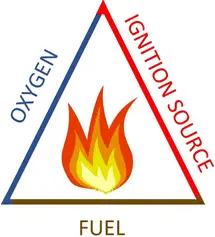

The Fire Triangle

Before we get into talking about the various types of heat-resistant surfaces, we need to preface our discussion with an explanation of how fires start.

There are three components necessary for a fire and they can be depicted in a “Fire Triangle.”

Image taken from http://umich.edu/~safeche/firetriangle.html

One component of that triangle is oxygen. A fire needs oxygen to survive. Without oxygen, there will be no fire.

The fuel, or combustible material, is the second component necessary for a fire. The fire needs a fuel source, which is the material that is burned. Examples include wood, paper, gas, etc.

The third component of the Fire Triangle is the Ignition Source. This is the heart of the fire, or what starts the fire. The most common ignition source is a flame, but it can also come from a spark, such as from electricity, or lightening.

When talking about candles we can equate/transfer these same principles to describing how a candle burns. The fuel, or combustible material, is the wick and the ignition source would be the flame, such as from a match or lighter, that starts the fire.

What Makes Wood (Or Other Material) “Heat-Resistant”

Heat-resistant (aka “heat proof”) is defined as when material does not become hot very easily. Wood (or other material) is considered “heat-resistant” when it is not burned (or melted) easily by heat or fire and it is able to withstand burning for an extended period of time.

Heat-resistant wood is capable of withstanding extremely high temperatures and can withstand fire/flame without easily losing its structure (or functionality).

Any type of wood (or fabric) can be treated to be more “heat-resistant” (or “fire retardant”). Making wood heat resistant requires combining it with other non-combustible materials. Heat-resistant wood can also be made by pressure treating it with non-combustible materials, such as fire-retardant chemicals.

When the heat-resistant, treated wood is exposed to extreme temperatures, it produces low-level acids, which limit the production of gases that would normally spread the fire. Therefore, the wood “chars,” instead of bursting into flames, and the fire does not spread as easily.

Classes of Heat-Resistant Wood/Material

There are three classes of Heat-Resistant Wood, called Class A, B, and C, or Class I, II, and III.

Class A (or Class I) heat-resistant wood can withstand direct contact with fire for 30 minutes and the rate of flame travel is minimal. This is the highest grade of heat-resistant wood. It is considered similar to, or has similar burn properties of, concrete. Examples of Class A material include brick, concrete/cement, and specifically fire-retardant treated plywood (plywood that has been specifically treated to be fire-retardant).

Class B (or Class II) heat-resistant wood has a moderate rate of flame travel and will ignite and burn in less than 20 minutes when exposed to direct contact with fire. Examples of Class B material include Western Red Cedar, West Coast Hemlock, and Spruce wood.

Class C (or Class III) is the least “heat-resistant” wood. It can only withstand direct contact with fire for a few minutes and has a high rate of flame travel. Examples of Class C materials are particle board, yellow birch, Douglas Fir, Medium Density Fiberboard (MDF), Idaho White Pine, Maple Wood, Red or White Oak, Lodgepole Pine, Ponderosa Pine, and (non-treated) plywood made of oak or pine.

Table of the Classes of Heat-Resistant Wood/Material (Class A, B, C) and Examples

| Class of Heat-Resistant Wood/Material | Examples |

| Class A (aka Class I) | Brick Concrete/Cement Granite Fire-Retardant Plywood (specifically treated) |

| Class B (aka Class II) | Western Red Cedar West Coast Hemlock Spruce Wood |

| Class C (aka Class III) | Particle Board Yellow Birch Douglas Fir Medium Density Fiberboard (MDF) Idaho White Pine Maple Wood Red or White Oak Lodgepole Pine Ponderosa Pine Non-treated Plywood made of oak or pine |

Heat-Resistant Surfaces

Heat-resistant surfaces are those that do not burn easily or heat up quickly and are made to withstand warm temperatures. Good examples of heat-resistant surfaces that would be good to burn candles on include stovetops; kitchen countertops, such as granite; dining room tables, specifically with treated wood; and other tables, chairs, or shelves with fire-resistant, treated wooden surfaces.

It may be surprising to hear that wood is heat-resistant. Many dining room tables, living room furniture (side tables, coffee tables, etc.), and bedroom furniture (night stands, dressers, etc.) are made of fire-resistant, treated wood.

You can also buy candle holders or plates, which are usually made of glass or metal that is heat-resistant. These provide a safe surface to burn your candle, even if you are not sure the table or surface you are setting the candle holder on is heat-resistant. These can be found in the home décor section of any department store.

Brick, concrete, and cement are also other examples of surfaces that are considered “heat-resistant” and safe to burn candles on. Therefore, this is why granite countertops are considered a safe surface to burn candles on.

What NOT to Burn Candles On and Other Tips

Heat-Unsafe Surfaces

While this may seem fairly obvious, I thought I would include it anyway, just for completeness sake. Here are some examples of surfaces that are not heat resistant and would be unsafe to burn candles on:

- Plastic. Plastic is not heat safe and melts easily when exposed to heat or fire. Do not burn candles on any type of plastic plate or holder. It will melt. The candle could tip over and start a fire.

- Tablecloth or other fabric surface. Most fabrics are not heat-resistant, unless they have been specifically treated to be fire-retardant, such as a fire blanket. I would not advise a candle be burned on any tablecloth or other fabric surface.

- Tin is not heat resistant and is, in fact, a heat conductor. Therefore, if you were to heat a candle on a tin plate or other tin surface, it would warm up rather quickly. It would be considered unsafe to burn a candle on a tin surface.

Tips

- Do NOT burn a candle on an unstable surface. Any type of unstable surface that could cause a candle to tip over or the candle wax to drip is unsafe.

- Make sure any dripping wax does not drip on a surface that can catch fire, such as paper or cloth. So, the surface, whether it is a plate or table, should not have flammable material on it.

- Do NOT burn a candle under a wooden kitchen cabinet. Although it may be safe to burn a candle ON a kitchen countertop, such as one made of granite, it is not advisable to place the candle directly underneath a kitchen cabinet, made of wood, especially if the wood is not fire-retardant, heat-resistant, treated wood. Even if it is, the candle will still leave a burn mark on the bottom of the cabinet.

- Do NOT burn a candle on paper material, such as a sheet of paper or a paper plate. Paper is highly flammable and any dripping wax or even burning a candle on a paper plate or sheet of paper is highly unsafe and dangerous.

How To Make Wood Heat-Resistant

There are simple, at-home, paint-on or spray-on materials/chemicals that can be bought at any home improvement store, farm/gardening stores, chemical supply dealers, or on-line that can be used to make wood heat resistant. Another method involves dipping the wood in a special solution of these non-combustible chemicals.

Here is one method I found which uses the spray-on or paint-on method, 4 chemicals, and water.

For this recipe, you will need:

- 2 quarts of water

- ½ cup zinc chloride

- ¼ cup ferric chloride

- 3 Tbsp. boric acid

- 3 Tbsp. ammonium phosphate

Directions:

- Mix all four chemicals into 2 quarts of water.

- You can spray or paint 2-3 coats of this solution onto the wood.

How to Make Fabrics Flame Retardant

Here is a “recipe” I found using two different methods to make fabrics flame-retardant.

Method 1: Water and Borax

Ingredients:

- 1 gallon HOT water

- 13 oz. borax (such as a box of 20 Mule Team Borax)

Directions:

- Add the borax to the water and stir until fully dissolved.

- Pour the solution into a spray bottle, shake, and spray onto the fabric.

- Let the fabric dry.

Method 2: Borax and Boric Acid (for a “Highly-Resistant Solution”)

Ingredients:

- 9 oz. borax

- 4 oz. boric acid

- HOT water

Directions:

- Mix the borax, boric acid, and water together.

- Spray onto the fabric and let dry.

*Important Note: For both methods, you will have to reapply the solution after washing the fabric, because the borax and boric acid will come out in the wash.

I hope you found this post helpful and happy fire-resisting and flame-retarding!